電液伺服數(shù)控折彎機

"The strength with simplicity"Welded in single piece, the solid body structure easy to be handled especially during the shipment. The robust machine frame ensure the bending accuracy of the machine at

Learn more

On Demand Customization Process intelligence

Laser cutting solutions Provider

On Demand Customization Process intelligence

Welded in single piece, the solid body structure easy to be handled especially during the shipment. The robust machine frame ensure the bending accuracy of the machine at all time. Machine’s integrated hydraulic control system maintain the stability of hydraulic circuit and bending performance. Enchanted machine appearance and simple design, powered by hydraulic drive system, provide smooth bending process and easy to operate. The bending table is equipped with a mechanical crowning system to ensure equal offset pressure especially bending longer parts, to get accurate angle.

Bending machine is a machine that use to press the workpiece into different shapes according to the requirements. It is one of important equipment in the sheet metal industry. The bending machine is assembled of working table, sliding block, back gauge, cylinder and etc.

| Serial number | Name | Value | Unit | |

| 125T/4000 | ||||

| 1 | Force | 1250 | KN | |

| 2 | Working table length | 4000 | mm | |

| 3 | Distance Between Frame | 3200 | mm | |

| 4 | Throat Depth | 360 | mm | |

| 5 | Stroke Length | 120 | mm | |

| 6 | Maximum Stroke Length | 370 | mm | |

| 8 | Stroke speed | Fast approaching | 140 | mm/s |

| Pressure | — | mm/s | ||

| Return | 120 | mm/s | ||

| 9 | Main motor | Rotation speed | 1460 | r/min |

| Power | 7.5 | KW | ||

| Model | ESMG1-11C20CD-A3A1F | |||

| 10 | Gear pump | Pressure | 31.5 | Mpa |

| Flow | 10 | ml/r | ||

| Model | CP1-40-P-25-R China-USA joint venture Hytec | |||

| 11 | Maximum Hydraulic working Pressure | 19.8 | Mpa | |

| 12 | Dimensions | Length | 4010 | mm |

| Width | 1950 | mm | ||

| Height | 2700 | mm | ||

| Hydraulic System | Germany / Rexroth | |||

| Electrical components | France / Schneider | |||

| Sealing elements | NOK Japan/ NOK | |||

*Standard Reference JB/T22572-1999

CypCut will automatically optimize the errors when import drawing, delete duplicates and invisible graphic, smooth curve and join line segments etc.

Graphical design of technique setting, quick and easy to finish setting of lead line, micro-joint and kerf width compensation etc. of single or large quantity parts.

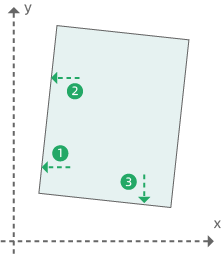

CypCut provides floating and workpiece coordinates for small and large quantity production.

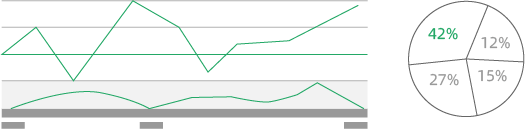

Thorough and timely statistic of machine production to help you manage the task schedule.

Support capacitance and photo-electric sensing to find workpiece edge and offset sheet placement angle.

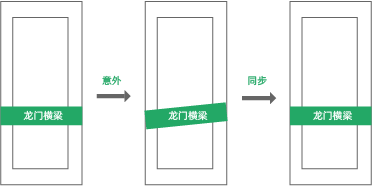

Auto correct the dual-drive position error each time after machine axes return origin.

| Control software | UltraCut |

| Bus station | CypTronic-EP PC |

| I/O station | HPL2720E BUS I/O terminal board |

| BCL4516E BUS I/O extension board(optional) | |

| Power supply | 24V DC/5A |

| PSO | Support 9 laser control modes, laser on interval 0.1μm-10μm can be adjusted |

| Motor control | Support up to 32 EtherCAT servo axes control in same time |

| Extension | Support up to 32 EtherCAT I/O stations |

| Acceleration | Maximum control acceleration 5G |

| Precision | Theroical control precision ±1um |

| Work environment | Temperature: 0~60℃ |

| Humidity: 10%~90%RH(no condensation) |

| Function Features | Support laser position synchronized output (PSO function), laser output interval 0.1-10μm. |

| Support 9 laser control modes, and compatible with various ultrafast laser brands. | |

| Communicate with laser by RS232 and Ethernet for parameter and status access. | |

| Support technique of transition line, lead line, Fly Cut, speed turning point, speed adjust in curve position. | |

| Support dual-Y structure production. | |

| Support to edit and execute parallel PLC process. | |

| Compatible with ModbusTCP, ADS and other standard protocols to guarantee online production. | |

| Provide optional vision positioning module to locate production by circle and cross mark. | |

| Control performance | Communication: RTOS real time core, signal cycle 1ms. |

| Precision: control precision 1μm. | |

| Support compensate pitch error from interferometer measure data, also support offset mechanic orthogonality. |

Suitable for cutting pipes of various metal materials, thicknesses, and shapes, it can meet the needs of different industries. For example, in fields such as mechanical manufacturing and construction, laser cutting machines for pipes are widely used.

????YD Laser Technology Co., Ltd.It is a professional R&D and production company Laser cutting machine A modern manufacturing enterprise. Since its establishment, the company has focused on optimizing and integrating resources in various aspects such as technology, quality, application, and market. Laser cutting machines guided by "high efficiency, high performance, and high precision" are widely used in various fields such as automobiles, steel, ships, machinery, aerospace, national defense, and rail transportation.Yida LaserFocusing on large, medium, and small format laser cutting machines. Centered around the business philosophy of "establishing a business with precision and winning with quality", we continuously improve product quality and gain the trust and support of our customers! To learn about the latest product quotations, you can contact our website http://www.ww158.cn/ We will contact you as soon as possible on the phone number provided.

If everyone is interested in our Electric Servo CNC Hydraulic Bending Machine If you have any further questions, please click on our website for consultation:http://www.ww158.cn/

This product specification may differ from the description subjected to countries rules and regulation. We reserve the right to amend according to technology, equipment model, price and range of accessories. Please contact your local agent to find out more about our products.

Wechat Scan QR Code

Copyright © 2024 YD Laser Technology Co., Ltd. .All Rights Reserved

Page execution time -62,009.4800 seconds, 11349 Data Query!

Page execution time -62,009.4800 seconds, 11349 Data Query!